All the limited slip differentials in the GT L.S.D. Series were tested in actual battle in All Japan Grand Touring Championships. They were used during the 2002 season by the GT500 XANAVI NISMO GT-R and the GT300 Daishin Advan Silvia. They are currently favorites at the D1 Grand Prix, at tuning car races and at touring car endurance races such as the Super Taikyu. From street racing to circuit and drifting, you'll find an LSD to fit your needs here.

The GT L.S.D. Series comes in a kit format with everything needed: LSD oil, side bearings, oil seals, cover gaskets, ring gear bolts and side flanges (kit contents may change depending on the vehicle in which the LSD will be installed). Each kit is ready for installation without any need for additional parts.

The NISMO GT L.S.D Series

The overall performance of an LSD is naturally tied to the locking of left and right shafts, but do you really know to what extent the actual locking performance (generated torque) is transmitted to the shafts? In the case of poorly manufactured LSDs, the generated torque delivered to the left and right shafts can be quite different. This imbalance can make controlling the vehicle difficult during acceleration and deceleration (in the case of a 2-way), a situation that forces the driver to execute extra steering maneuvers. It will also make suspension and brake adjustments difficult, at which point installing the LSD makes no sense at all. The extreme precision of the GT L.S.D. series leverages large capacity with uniform torque to both the left and right shafts. GT L.S.D.'s stable, high traction performance permits fine tuning of both brakes and transmission settings.

The schematic below compares the performance of the GT L.S.D. with LSDs typically found on the market from the point where the LSD becomes effective through to locking. You can see that generated torque is uneven to the left and right with the LSDs from other manufacturers, and it is clear that the GT L.S.D. distributes torque evenly to both shafts. When generated torque is not evenly distributed, acceleration on slippery roads becomes uncontrollable, which forces the driver into needless corrective steering, especially when cornering. Furthermore, when the driver feels a difference between left and right cornering, this usually leads to readjusting the suspension.

In the racing world, it's common knowledge that a precision LSD is a must before starting a fine tuning of the suspension or brakes. The NISMO GT L.S.D. design was born from this kind of thinking and experience.

This example should make it easy to understand why GT L.S.D.'s uniform torque means superior control.

LSD Performance

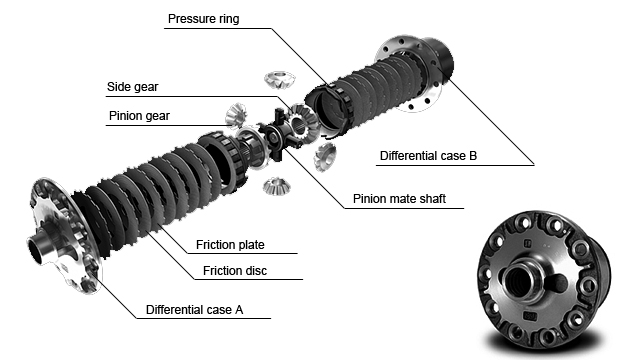

It's easy to increase LSD performance by increasing plate size or increasing the number of plates but extremely difficult to fix the plates exactly enough to ensure their operation within the narrow space of an LSD case. As NISMO began developing the GT L.S.D., it re-examined the plates, gears and case, then developed new specifications for the finest movement of every part. From slip to lock, we sought the most exact measures for ultimately precise and smooth slip, so that we could provide the highest quality possible in an LSD. The high-quality, high-performance GT L.S.D. series, which overwhelms the competition, has been created for people who know what LSDs are all about.

Advanced Manufacturing Precision

The greatest disadvantage in increasing plate size or number is a resulting reduction in the size of the plate teethe or in the groove area of the side gear and case. This adds up to poor slip stability as well as a reduction of plate strength because of thinner plates. The GT L.S.D. series features plates with 16 outer and 8 inner precision tooled teethe manufactured to exacting standards in a dedicated, high-tech production facility for the highest slip performance attainable. Rather than focus on securing some meaningless oil line, we concentrated on stabilizing slip performance. The plates assembled in the LSD function in the same way as a rag clutch, shifting from slip to lock. When manufacturing standards are lower and the plates are badly manufactured, they do not lock correctly but only partially. The badly made LSD is thrown into an unending slip-lock-slip-lock cycle that causes gear oil temperatures to rise while reducing product lifespan due to plate judder vibrations.

In an LSD, torque is generated when the pressure ring opens and the plate moves from slip to lock to produce the "moment of force". In the schematic below, the gray area representing the operation of another manufacturer's LSD is wide and amorphous, whereas the blue GT L.S.D. area is thin and concentrated. A wide line is evidence that though the plates are slipping, the LSD is just barely engaging the locked state. Unnecessary slippage is something that should never happen in an LSD. It is not only inefficient but has a very negative effect on driver handling. This is reflected in driver comments such as: "Angle handling is very unstable. Something's weird", "Starting a drift was no problem, but I couldn't hold it" or "Oversteering and understeering are way out of whack". On the other hand, the concentration of the GT L.S.D. blue area shows that the LSD is moving from slip to lock very precisely and without any unnecessary slippage both during acceleration and deceleration. Installing a GT L.S.D. is the shortcut to improved driving technique as well as vehicle tuning.

Fitment

This 1.5 Way LSD unit fits a variety of differentials including the following:

View this part in the NISMO Japan Catalog. Check out a list of all available Nismo Competition Parts for all models HERE.

|